While vacuum valves rarely make headlines, their design variations (ball, butterfly, and gate valves) each solve unique challenges in industries shaping our daily lives. Let’s explore how these critical components operate behind the scenes.

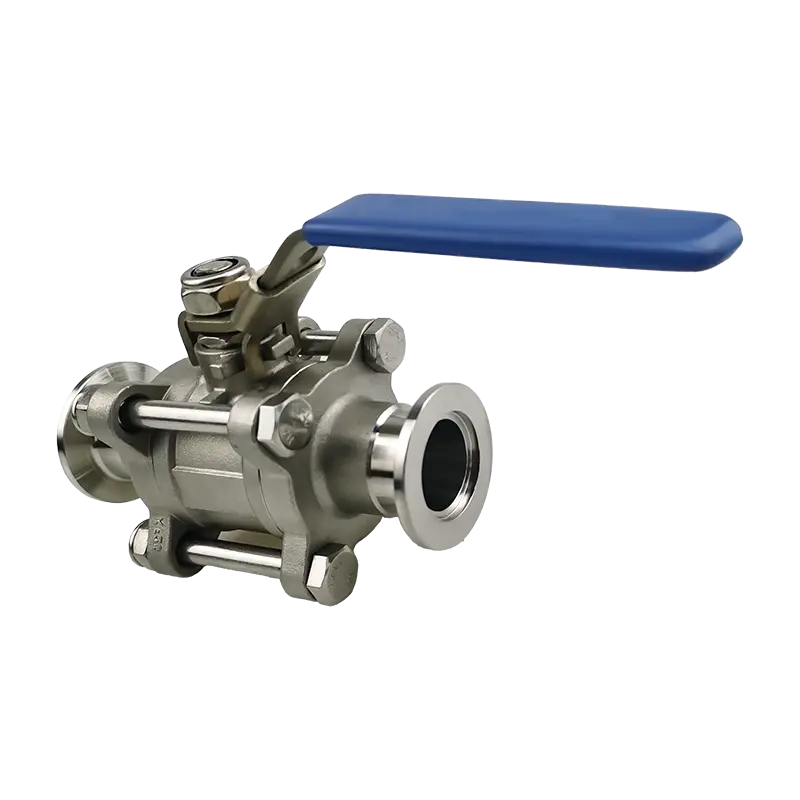

Vacuum Ball Valves: Speed Meets Precision

In semiconductor cleanrooms, where a single dust particle can destroy a $20,000 silicon wafer, ball valves act as rapid-response sentinels. Their quarter-turn operation seals chambers in milliseconds during chip etching. For example, TSMC’s 3nm fabrication lines use electropolished stainless steel ball valves with mirror-smooth surfaces (Ra < 0.1μm) to prevent micro-scratches on wafers. A recent upgrade to ceramic-coated balls reduced particle generation by 83%, extending maintenance intervals from 2 weeks to 6 months.

Vacuum Butterfly Valves: Mastering Delicate Flows

When packaging COVID-19 vaccines, Pfizer’s filling machines rely on butterfly valves to control nitrogen flow within 0.1% accuracy. Their thin disc design minimizes turbulence, which is critical when handling fragile mRNA lipids. In fusion reactors like ITER, 2-meter-wide butterfly valves regulate hydrogen plasma containment. Engineers at MIT recently tested a graphene-reinforced variant that withstood 10,000 cycles at 1500°C, a 400% durability improvement over traditional models.

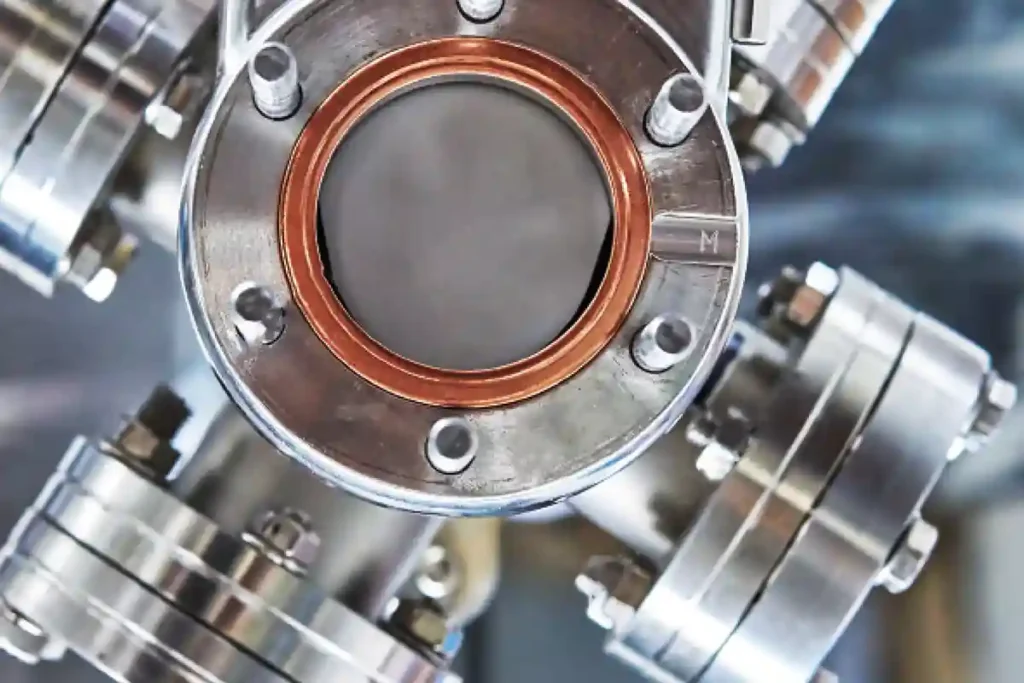

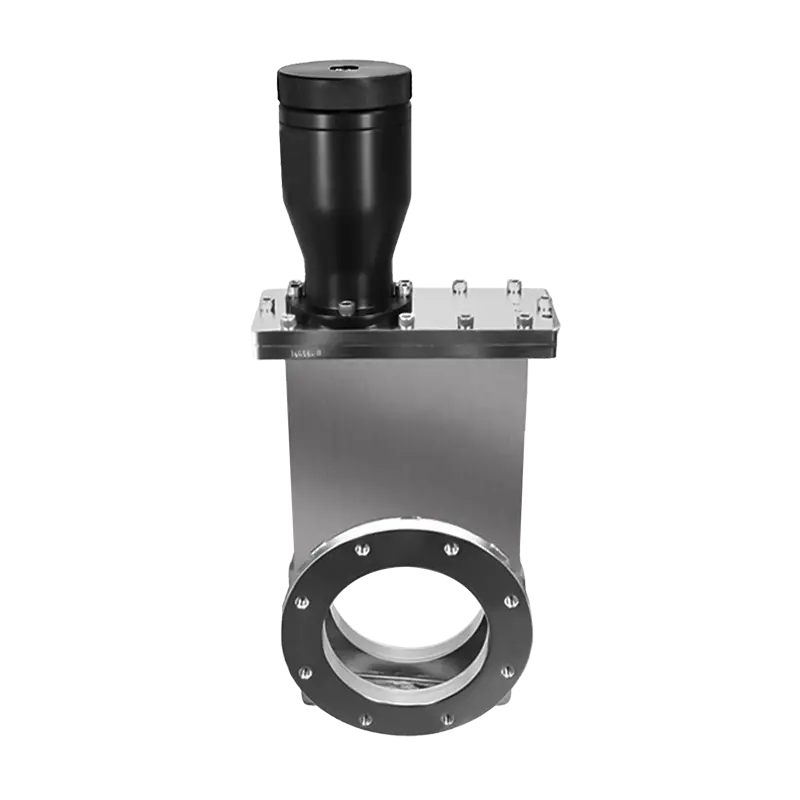

Vacuum Gate Valves: Built for Extreme Conditions

SpaceX’s Starship fuel systems depend on gate valves to handle -253°C liquid methane without leaking. Unlike ball valves, their sliding plates provide zero-clearance seals, a feature vital when 1 gram of leaked fuel could destabilize a lunar landing. In synchrotron radiation facilities, copper-sealed gate valves block X-ray backflow 500 times per hour. Researchers at CERN found that replacing conventional lubricants with diamond-like carbon coatings reduced wear by 92% in high-radiation zones.

Material Choices That Make or Break Performance

Semiconductor-grade aluminum: Used in ball valve bodies, its natural oxide layer resists plasma corrosion during wafer cleaning.

Space-grade elastomers: Butterfly valve seals in the James Webb Space Telescope use a custom fluorocarbon blend releasing less than 10⁻¹¹ Torr·L/sec of gases, preventing lens fogging in deep space.

Neutron-resistant coatings: Molybdenum-coated gate valves in nuclear reactors maintain seal integrity despite neutron bombardment altering their crystalline structure.

Industries Pushing Valve Innovation Forward

Quantum Computing: IBM’s dilution refrigerators need valves operating at 0.01K (-273.14°C). Superfluid helium-compatible designs now use single-crystal sapphire seats.

Vertical Farming: Aeroponic systems using butterfly valves mist roots with 50μm nutrient droplets. Clog-resistant nozzles boosted crop yields by 40% in Tokyo’s underground farms.

Carbon Capture: Ball valves in direct air capture plants endure 10,000 ppm CO2 concentrations. A nickel-alloy innovation at Climeworks reduced corrosion repairs from monthly to biannual.

The Next Frontier: Valves Get Smarter

Self-monitoring ball valves in offshore oil rigs detect seal wear via embedded piezoelectric sensors, alerting engineers three weeks before failure.

AI-driven butterfly valves at Nestlé’s coffee factories adjust airflow 100 times per second, maintaining optimal roast profiles with 0.2°C precision.

Mars-ready prototypes tested in Chile’s Atacama Desert combine shape-memory alloys and dust-repellent nano-textures for 50-year maintenance-free operation.

From smartphones to Mars missions, vacuum valves prove that the smallest components often hold the greatest responsibility. Their evolution isn’t just about engineering; it’s about enabling what we once thought impossible.

Elitevak | Premier Industrial Vacuum Solutions

Elevate Your Engineering and Manufacturing Excellence