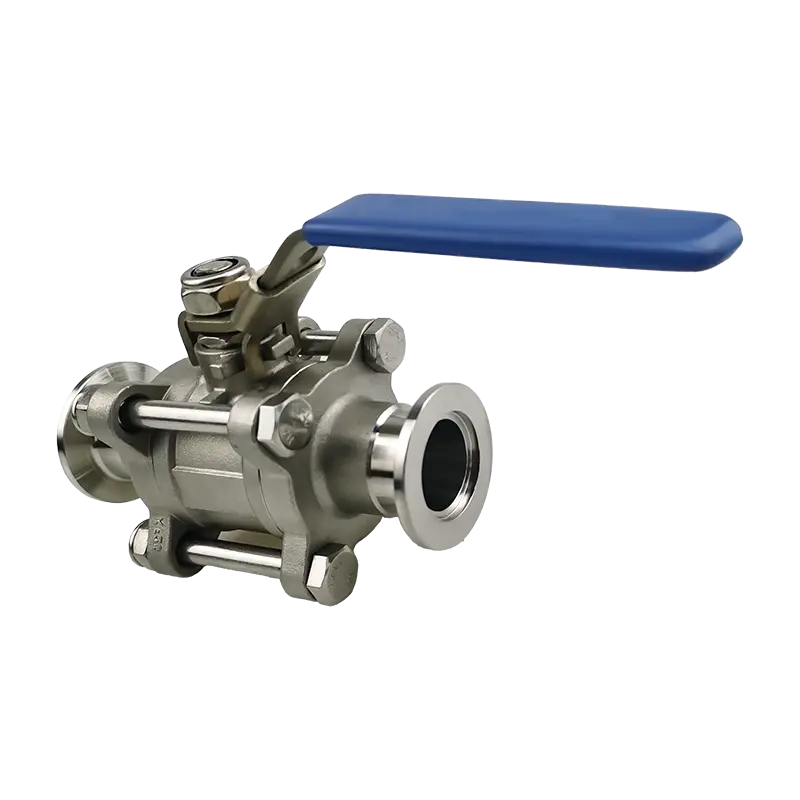

Vacuum valves are crucial components in diverse industries like aerospace, pharmaceuticals, semiconductor manufacturing, and petrochemicals, due to their role in establishing, controlling, and sustaining vacuum conditions essential for various industrial processes.

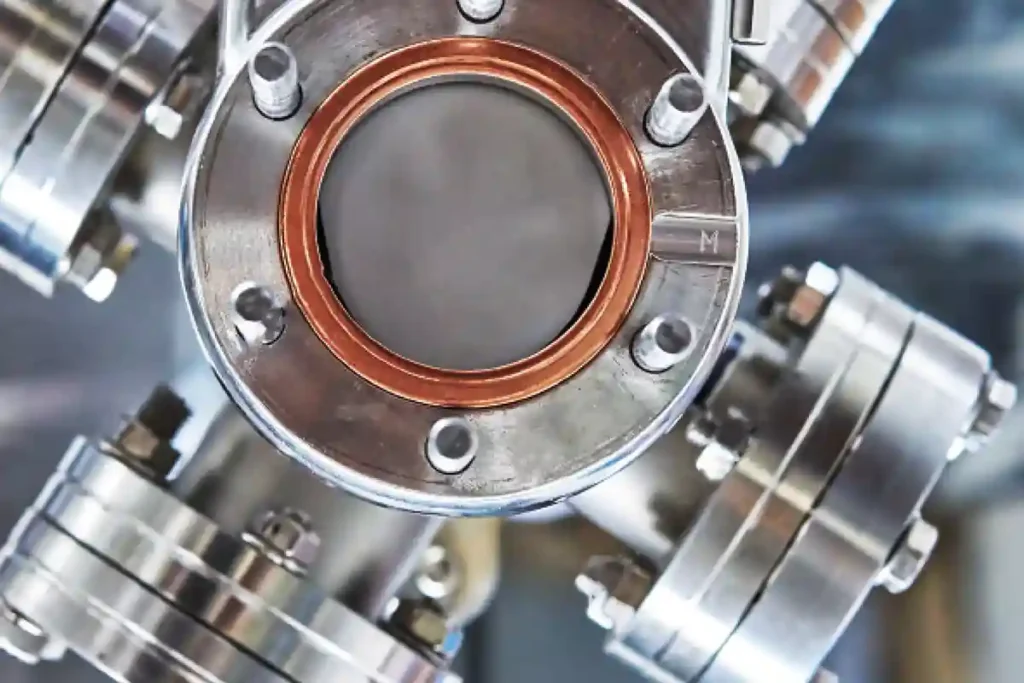

The Impact of Quality on Leak Prevention

A key advantage of high-quality vacuum valves is their ability to prevent leaks. Effective sealing is critical as even minor leaks can severely undermine system efficiency, accuracy, and contamination risks. Top-tier vacuum valves employ advanced sealing technologies and undergo rigorous testing, including helium and pressure testing, to ensure reliable performance under extreme conditions. These valves are also built to withstand high temperatures, corrosive environments, and excessive pressure, which enhances their integrity and reliability.

Longevity and Cost Savings

The construction quality of vacuum valves not only prevents leaks but also ensures system durability. Operating under harsh conditions, these systems benefit from robust materials and stringent quality controls that extend their lifespan. This reduces the frequency of valve replacements, cutting down on maintenance costs and operational downtimes. The financial impact of downtime in industries reliant on vacuum systems can be significant, with costs running into thousands of dollars per hour due to halted production, missed deadlines, and additional repair expenses.

Material Selection Enhances Compatibility and Efficiency

Selecting the right materials for vacuum valves is vital for ensuring compatibility with specific vacuum environments. Material characteristics such as outgassing rates, temperature resistance, and chemical resistance are critical. Materials like aluminum and stainless steel are preferred for their low outgassing rates and minimal particle generation, which is crucial in maintaining cleanliness and optimal system pressure. Proper material choice also boosts operational efficiency, enhancing the overall performance and reliability of vacuum systems.

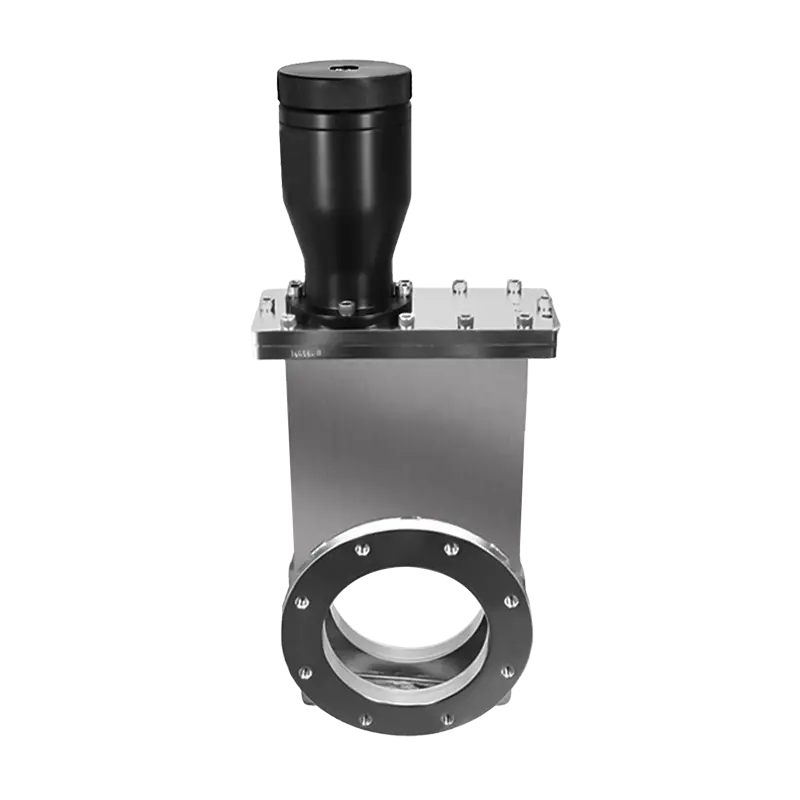

Diverse Industrial Applications of Vacuum Valves

Vacuum valves find extensive use across various sectors:

- Semiconductor Manufacturing: Here, vacuum valves regulate the flow of material onto silicon wafers for microprocessor production. Precision in flow control is imperative to ensure the quality of the final products.

- Health Care: In medical imaging devices like MRI machines, vacuum valves help maintain the necessary vacuum, affecting the precision and reliability of the imaging.

- Aerospace: In space exploration, vacuum systems are essential for simulating outer space environments and ensuring the reliability of spacecraft over extended periods.

In addition to these, vacuum valves are integral to processes in industries such as vacuum coating and industrial processing, where they ensure precise control and continuous regulation under demanding conditions.

Elitevak | Premier Industrial Vacuum Solutions

Elevate Your Engineering and Manufacturing Excellence